|

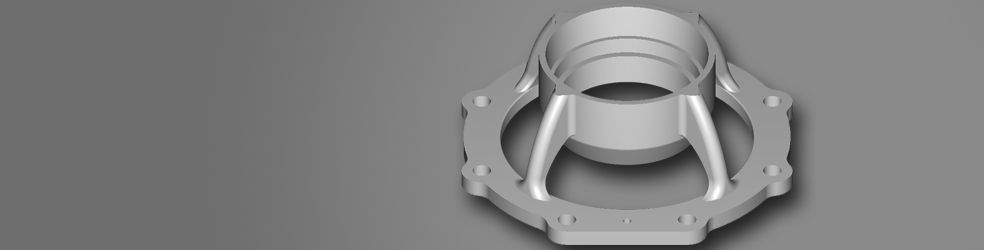

Sand CastingSand combined with a suitable binder can be packed or rammed rigidly about a pattern. When the pattern is removed, a cavity corresponding to the shape of the part remains. The upper half of the pattern is called the cope and the bottom, the drag. Each half is formed separately then the cope is placed on top of the drag portion. A metal jacket or flask is placed around the mold which holds the four sides in place. Ideally suited for small and medium quantities sand castings are produced in aluminium, Brass and Bronze based alloys up to a weight of about 80 kg. |

|||||||||||||||||||||||||||||||||||

our solidity

is equity

Innovation and flexibility, quick and

our solidity

is equity

Innovation and flexibility, quick and our aim is

Dedicated

To conducting business affairs using

our aim is

Dedicated

To conducting business affairs using encourage

Business

Success and growth with our

encourage

Business

Success and growth with our